The Ultimate Guide to Fastener Materials and Coatings (All You've Ever Need To Know)

Choosing the type of fastener, such as bolt, rivet, screw, clamp, etc. is highly important, what the fasteners is made of makes a huge difference in the performance of the fasteners as well. Fasteners come in all sorts of materials and coatings.The type of material can define what kind of conditions that fastener can be used for. This is because different types of materials offer different properties such as resistance to corrosion, strength, re-usability, stability, and lastly, difference of cost. If you are replacing a fastener, it is important to match what you are replacing with the same material. It's not always safe or smart to choose the strongest or the most affordable material, as it might not be the most compatible or beneficial material for the application.

We're going to thoroughly break down the different types of materials and coatings. We'll be going over all types, just not the popular ones, so that you can be as informed as possible. Keep this article saved in your bookmarks, it can be a very useful guide to refer to when you are choosing fasteners.

Materials

Stainless Steel

Stainless steel is a highly reliable material for fasteners, which is one of the reasons so many fasteners are made from it. Stainless steel is an alloy (mixture of two or more elements) of chromium and low carbon steel. This material offers high resistance to corrosion and even if the metal has been scratched or damaged during application, it does not decrease its resistance to corrosion. This is due to the anti-corrosive properties inherent to this alloy.

Which do you think is stronger; stainless steel or regular steel? Due to containing low carbon, stainless steel alloys will not harden with heat treatment. Thus, stainless steel bolts are slightly stronger than un-hardened steel fasteners, but they are much weaker than hardened steel fasteners. Stainless steel is also magnetic, but not as magnetic as steel.

There are a few different grades of stainless steel, these grades make them more specific to different applications.

- 18-8 Stainless Steel: 18% chromium and 8% nickel. This type of stainless steel is used for producing fasteners for industrial applications. 18-8 is often used to identify products made from 300 series S.S. This type of stainless steel is Austenitic.

- Stainless Steel 316: Optimal for medical, chlorine and saltwater applications. The chromium content in this material is slightly less than 18-8 S.S, and the nickel content is slightly increase. Also, a tiny bit of molybdenum is added into the alloy. This results in a more corrosive resistant material. Typically more expensive than 18-8 S.S. This type of stainless steel is also Austenitic.

- Stainless Steel 410: Harder than 18-8 S.S, this grade is not as resistant to corrosion compared to S.S. 316. It can be increased by hardening and tempering. Generally used for applications that involve mild corrosion, heat resistance, and high strength. It contains 11.5% chromium. This type of stainless steel is Martensitic.

- Ferritic Stainless Steel: This type of S.S. is mainly used for decorative purposes. The main part of this alloy is chromium and they have an extremely low carbon content, as well as no nickel. They're found in the 400 series.They are more corrosive resistant than martensitic grades, but less than austenitic grades.

- Duplex Stainless Steel: Duplex S.S. is a mix of 50% austenitic and 50% ferritic steel. Consists of a high percentage of chromium (22-24%) and 4-5% nickel. They are corrosion resistant and do not crack under stress. They also provide more strength than fully austenitic steels.

Steel

Steel is the most popular material fasteners are made from; it makes up 90% of all fasteners made each year. It's very durable and inexpensive.

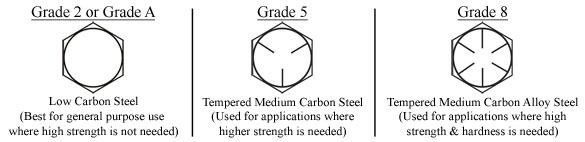

You can find these with and without a treated surface. They're available with zinc plating, galvanization, chrome plating, as well as just plain. Steel fasteners come in various grades, most commonly Grade 2, 5, 8 , and Alloy Steel. There is likely a yellow or bluish zinc coating or galvanization on Grade 2, 5, and 8 fasteners.

You can determine the grade of the bolt typically by the head, see diagram below. Other grades are available but are not as commonly used.

- Grade 2: The most common steel grade for fasteners and is the most affordable. These have no head marking.

- Grade 5 / Grade F: Mainly used in automotive applications. These are hardened for more strength. Usually feature 3 evenly spaced out radial lines on head for identification. Grade F nuts are used with Grade 5 bolts.

- Grade 8 / Grade G: This grade is a hardened even more than grade 5 and is used for higher stress applications, such as automotive suspensions. They feature 6 evenly spaced out radial lines on head for identification. Grade G nuts are used with Grade 8 bolts.

Image from http://www.wholesalebolts.com/hexboltszincplateds...

- Alloy: Highs strength alloy steel bolts are heat treated for additional strength, however, they are very brittle. They are not plated and have a distinct dull black finish.

Brass

Brass is a zinc and copper alloy. It can conduct electricity and is anti-corrosive. This type of material is relatively soft, thus, limiting the versatility of use for this fastener. It has a high corrosion resistance and features a higher tensile strength to mild carbon steel. It is mainly used for it's appearance, it has a high sheen.

Aluminum

Aluminum fasteners are soft, light weight, and resist corrosion, even after being scratched during installation or being previously used. They weigh less than half that of steel. There are a variety of aluminum alloys used for fasteners, these alloys use elements like iron, manganese, magnesium, zinc, and copper.

Strength and melting point is increased by adding silicon to the alloy. Aluminum can be hardened, but also left unhardened. It has a high electrical conductivity and has a high luster finish. By volume, aluminum alloys are the most affordable of metallic materials.

Bronze

Bronze is an alloy made mainly of copper and tin, with a little amount of silicon (this material is called Silicon Bronze). It's extremely resistant to corrosion and chosen over brass because of it's higher strength. Mainly used in marine environments but also used in woodwork for its appearance. Bronze is on the pricey end of the spectrum for fastener materials.

Non-Metallic

Fasteners manufactured of non-metallic materials are usually lightweight and non-conductive. Aesthetically speaking, non-metallic fasteners are easily manipulated, however, they can quickly fall victim to deterioration in extreme environmental conditions. They are also not as strong as their metallic counterparts. Non-metallic materials include:

- Nylon

- PVC

- Wood

- Neoprene

- Polypropylene

- Polycarbonate

Uncommon Metals

- Copper: Copper is a very malleable metal with corrosion resistance. It has a very high conductivity compared to the rest of the fastener metals. Strength is increased when copper is alloyed with silicon, manganese, or aluminum.

- Nickel: There are three types: pure nickel, Monel, and Inconel.Nickel

is utilized when extreme strength, the ability to last in very high

temperatures,a discoloration resistance, and corrosion resistance are

required.

- Pure Nickel: Made of 99.4% nickel. Used in applications that require very high strength retention at extreme high and low temperatures.

- Monel: A nickel alloy made of up to 67% nickel and alloyed with copper, and small amounts of other elements like iron, manganese, carbon, and silicon. This material is stronger than pure nickel and highly resistant to corrosion. Highly used for marine applications and applications where there is exposure to various fluids and oxygen (Monel is resistant to acids and oxygen, making it a great material to use in the chemical industry).

- Inconel: Inconel is a type of nickel fastener used in extreme conditions such as temperatures of up to 1600°F. This is due to it's ability to keep its strength and resist oxidation at high temperatures, where aluminum and steel would deform.

- Titanium: Titanium fasteners are used on aircraft. They have an amazing resistance to corrosion and perform well in high-temperatures.

- Beryllium: Beryllium fasteners are only about 40% as heavy as titanium. They are brittle, thus limiting use.

Coatings/Platings

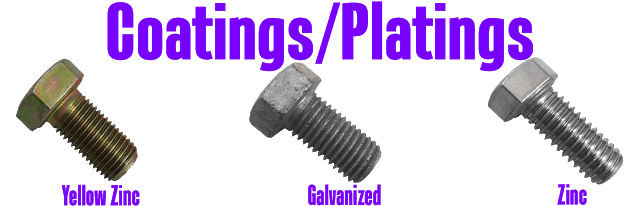

Coatings and platings are added to fasteners to ensure corrosion resistance and other protective purposes. They may also be added for decorative purposes (chrome) or conductive purposes (copper). Many fasteners are also left plain. There are different types of platings and coatings applied:

- Zinc Plating: Steel fasteners commonly are electroplated with zinc to increase resistance to corrosion. Zinc plating results in fasteners having a shiny, silvery grey appearance, or sometimes golden. This is respectively referred to as zinc or yellow zinc. The yellow coating is actually thicker and provides more protection. After the coating has been damaged, the possibility of rust is increased.

- Hot Dip Galvanizing: Galvanizing also involves adding a layer of zinc to the fastener. Hot dip galvanizing applies the thicket possible zinc coating onto the metal, providing the most superior corrosion resistance. Galvanized bolts are not compatible with non-galvanized nuts due to the thickness of the layer. Hot dipped galvanized fasteners are most often used outdoors, especially on the coast.

- Cadmium Plating: Gives slightly higher protection than zinc. Not used as often as in the past because it is toxic and not environmentally friendly.

- Phosphate Plating: This coating is thin and not as protective as zinc. Phosphate provides a good base for painting, usually used in automotives.

There are other types of coatings used for different purposes, but the above are the most common. The thickness of the coating can vary depending on the method, these include: zinc electroplating, hot dip galvanizing, or mechanical coating. The life expectancy of these coatings depends on the thickness of the coat, the environment of the fastener, and the application.

Here is a very unenthusiastic but informative visual of much of the information we've written above:

Here at Edmonton Fasteners and Tools Ltd. we specialize in fasteners and helping you find the right one for your application. With the help of our guide, we hope to help you find what you're looking for when the time comes. If you need any assistance choosing a fastener, feel free to call us at 780-484-3113 and speak to one of our experts. You can also email us at sales@edmfast.com. We'd love to help! Thank you for stopping by and we'll see you in the next post!

Recent Posts

-

Bissett is Universally Compatible, See Why and How

With Bissett's over 600 fasteners, you're bound to find the perfect fastener for your tool. You …2021 Mar 16th -

How To Choose Safety Gloves

We love healthy hands at Edmonton Fasteners. We’re not a skincare shop (clearly) but we d …2021 Mar 8th -

Three Easy Home Fixes with Gorilla Glue

Gorilla Glue is a household name because of one reason: it works. We carry Gorilla Glue at Edmo …2021 Feb 2nd