Buyer's Guide: Selecting the Proper Torque Wrench

Firstly, what is a torque wrench? A torque wrench is used to apply a specific torque accurately to a nut, bolt, or other fastener. It will typically have a gauge to indicate the amount of torque being applied. Torque wrenches are ideal for applications that require tight nuts and bolts without over-tightening. They're used mainly for automotive and industrial purposes. When it comes to choosing a torque wrench you must consider: the size you need and the style of wrench you want.

Torque Wrench Sizes & Applications

1/4" Drive - This size is ideal for short and little nuts and bolts. Use for applications requiring 4-21 foot-pounds.

3/8" Drive - This size is the most versatile of all

drives, if you're looking to only own one torque wrench. It works for

majority of nuts and bolts of vehicles. Use for applications requiring

15-75 foot-pounds.

1/2" Drive - Used on larger nuts and bolts for suspension, engine mounts, transmission mounts, etc. Relevant for 30 - 250 foot-pounds.

3/4" Drive - Majority of people do not need a torque wrench this large.

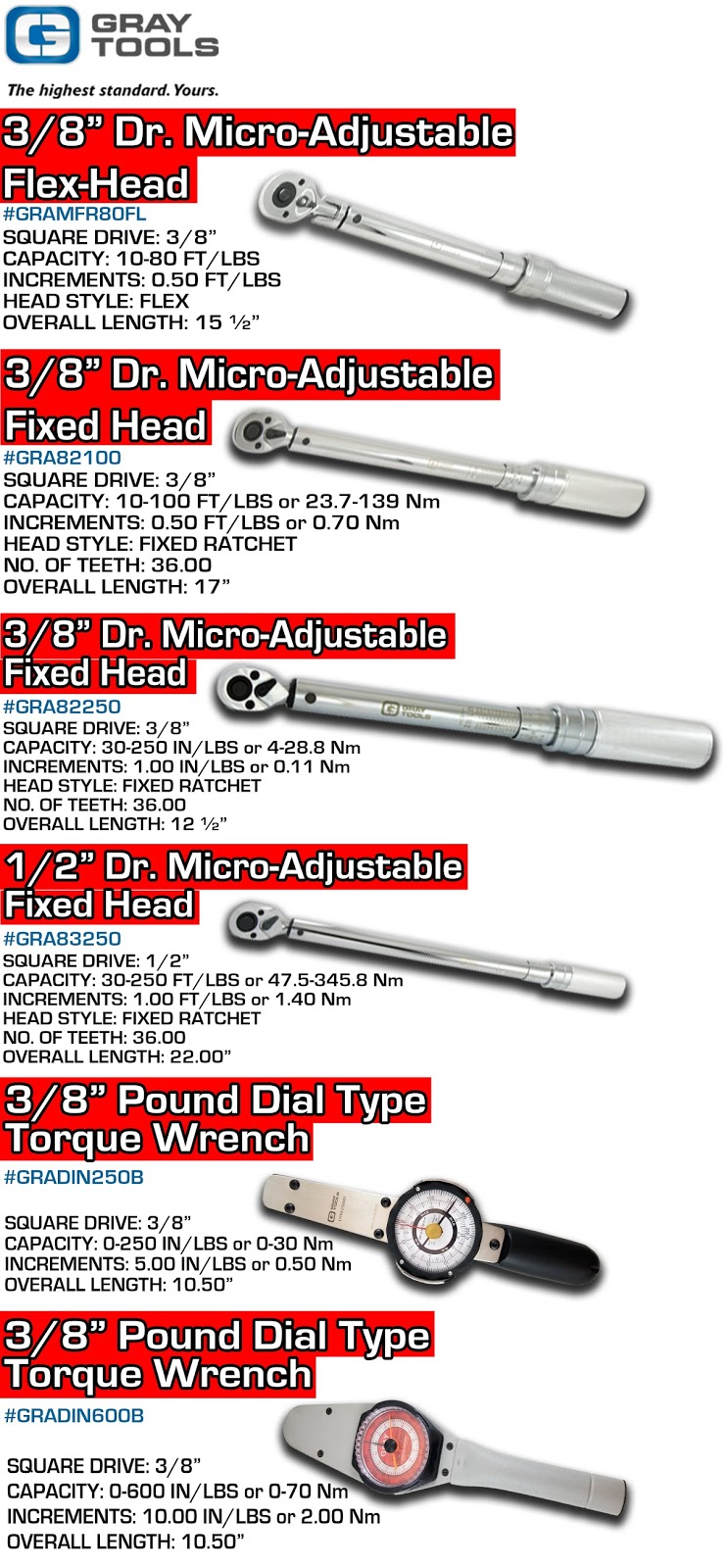

Below are some examples of

Gray Tools torque wrenches with their drive sizes and other specifications in proportion to their

size. You might notice some capacities overlap, although they overlap,

it's best to buy the right size torque wrench for your application

versus largest capacity range. You will experience the highest accuracy

in the middle of their range, so choose accordingly. As capacity

increases, so does the size of the wrench, making it harder to maneuver

in smaller spaces. A flex-head torque wrench is beneficial if you are

using it in a hard-to-reach place and need to hold the wrench in a

different angle.

Click here to see all Gray Tools torque wrenches at Edmonton Fasteners & Tools Ltd.

Types of Torque Wrenches:

Beam - The beam torque wrench is the oldest type and uses a simple pointer and scale to indicate the amount of torque being applied. This is the least accurate and least reliable form of torque wrench. It's the least expensive but also the lowest quality.

Clicker - The clicker torque wrench has a micrometer-type scale built right into the handle. You rotate the handle to a preset torque and when that torque is reached, you will here a "click" sound. This is the most common form of torque wrench. The above wrenches (except for the bottom two) are clicker torque wrenches.

Dial Type - The dial type torque wrench is considered to be one of the most accurate types. It's unique to other types of torque wrenches because it's final reading is not affected by the hand-hold position of the wrench.

Electronic - The electronic torque wrench features a digital reading, making it very easy to read versus a non-digital dial or scale. It also has various digital features like sensory, audible, and visual indicators that alert you when the desired torque has been reached.

The most optimal torque wrench should have a precise and accurate measurement system. whether it's foot-pounds or Newton meters or both. Each torque wrench should come with a calibration certificate.

We currently have a big sale on torque wrenches by Gray Tools going on now. and thanks for stopping by the EF blog! If you have any questions please comment below, email us, or call 1-780-484-3113 where one of our experts will gladly help you find what you're looking for!

Recent Posts

-

Bissett is Universally Compatible, See Why and How

With Bissett's over 600 fasteners, you're bound to find the perfect fastener for your tool. You're n …2021 Mar 16th -

How To Choose Safety Gloves

We love healthy hands at Edmonton Fasteners. We’re not a skincare shop (clearly) but we do off …2021 Mar 8th -

Three Easy Home Fixes with Gorilla Glue

Gorilla Glue is a household name because of one reason: it works. We carry Gorilla Glue at Edmonton …2021 Feb 2nd